News Excerpt:

India will start manufacturing the common antibiotic Penicillin G by mid-2024, three decades after the country’s last plant shut down.

More on the news:

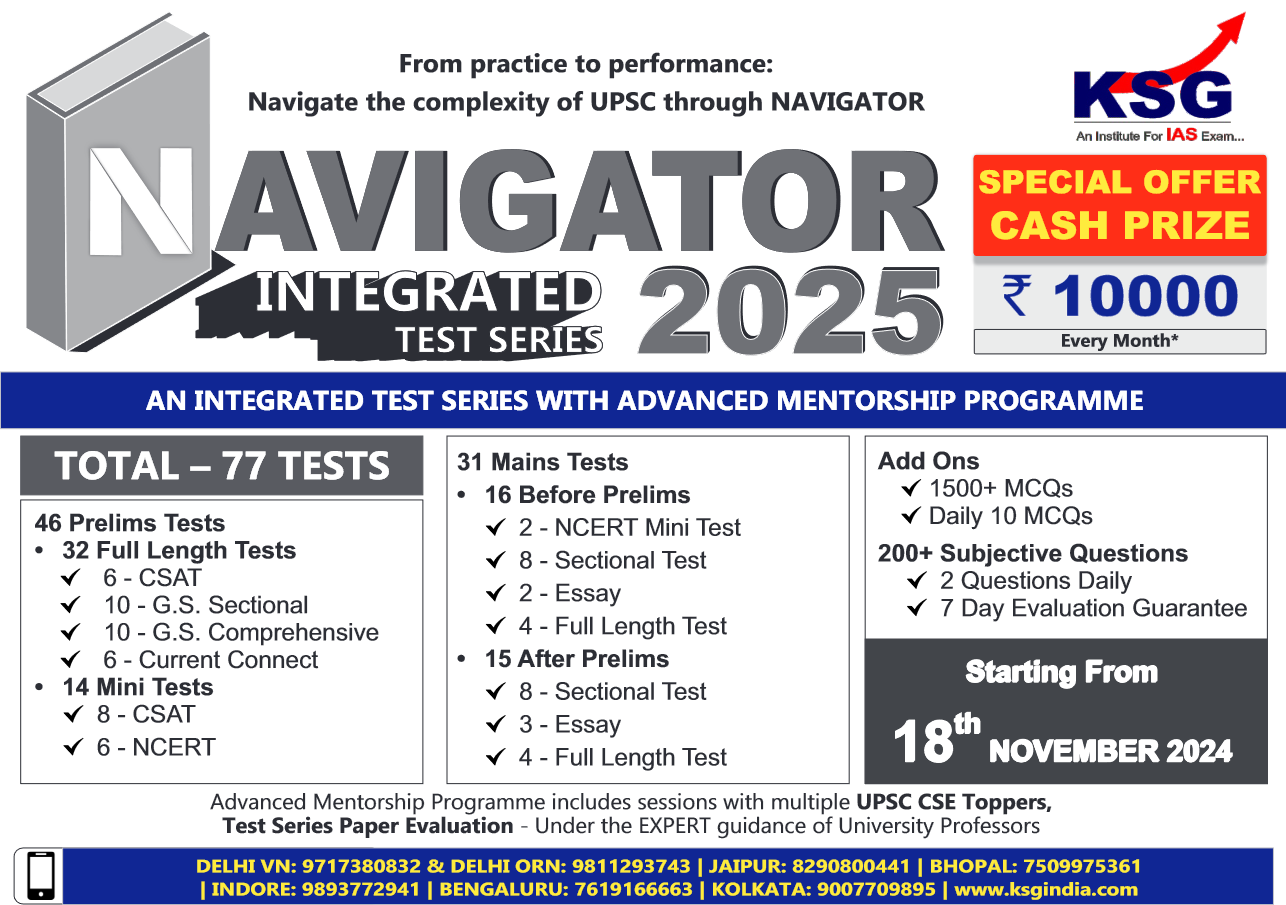

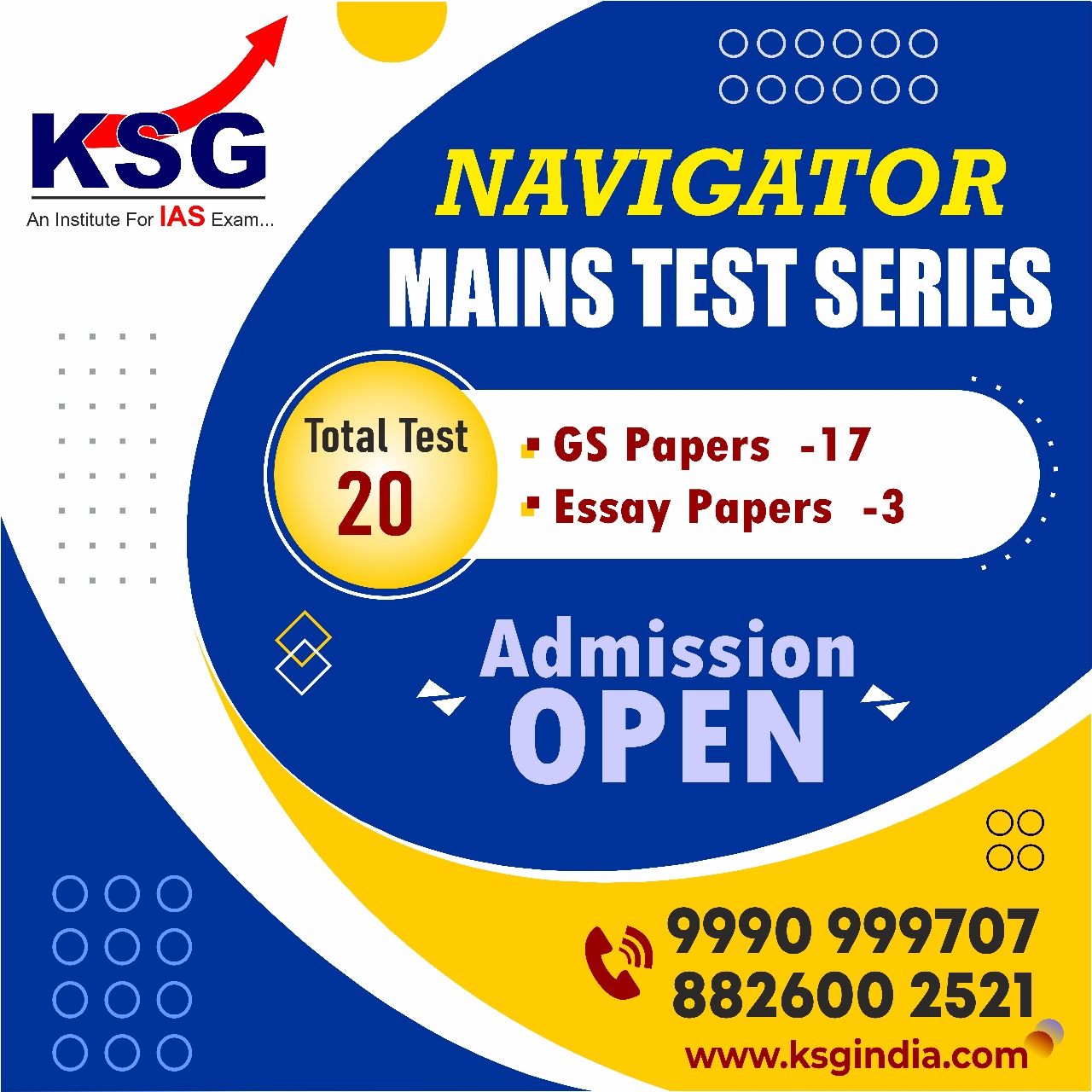

- This is one of the successes of the government’s Production Linked Incentive scheme launched during the pandemic to promote domestic manufacturing — the scheme incentivises companies on incremental sales.

About Penicillin G:

- Penicillin G is the active pharmaceutical ingredient (API) used in manufacturing several common antibiotics.

- Molecular Formula: C16H18N2O4S

- Penicillin G (potassium or sodium) is an antibacterial prescription medicine approved by the U.S. Food and Drug Administration (FDA) for the treatment of certain serious bacterial infections, such as pneumonia, meningitis, gonorrhoea, syphilis, and others.

- It is a natural penicillin antibiotic that is administered intravenously or intramuscularly due to poor oral absorption.

- Penicillin G may also be used in some cases as prophylaxis against susceptible organisms.

Why did penicillin manufacturing stop in India?

- Penicillin G, just like many other APIs that India manufactured, was phased out of production because of subsidy-driven cheaper chinese products flooding the market.

- The last plant to stop production of the antibiotic was Torrent Pharma in Ahmedabad.

- At least five companies, including Torrent, manufactured Penicillin G in the country in the 1990s.

- There were nearly 2,000 API manufacturers in India in the early 90s. However, nearly 10,000 units manufactured formulations.

- For them, cheaper Chinese products made more sense, especially at a time when the country’s economy was opening up and customs rules were relaxed.

- The Drug Prices Control Order — which capped prices of essential medicines — also ensured that more companies went for cheaper imported products.

- India used to sell it for around Rs 800 per kg then, but China brought the prices down to nearly Rs 400 per kg, making it unviable for Indian manufacturers.

Why did it take so long to restart?

- Need not felt:

-

- While the industry and government were aware of the decline in the production of APIs in India, as cheaper alternatives were available in the globalised world, there wasn’t much focus on restarting production within the country.

- The supply chain disruption caused during the pandemic was a wake-up call that we needed to be self-reliant.

- This led to the government launching the PLI scheme to support manufacturing within the country.

- Huge initial costs:

-

- Manufacturing an API, especially a fermented one like Penicillin G, is cost-intensive.

- Setting up a factory requires huge capital expenditure, and the company can only break even after a couple of years.

- Presence of China as a well-established supplier:

- China has scaled up manufacturing several-folds in the last three decades.

- Competing with the prices would require investments in bigger facilities.

What has been the impact of PLI schemes?

- There has been a decline in API imports since the launch of the PLI scheme.

- Take the example of paracetamol - before the pandemic, India imported two-thirds of the API needed; now, that volume has halved.

- The scheme envisages a support of 20% for the first four years, 15% for the fifth year, and 5% for the sixth year on eligible sales of fermentation-based bulk drugs such as antibiotics, enzymes, and hormones such as insulin.

- For chemically synthesised drugs, the incentive will be at the rate of 10% for six years on eligible sales.