GS Paper III

News Excerpt:

Gujarat's dairy cooperatives are showing the way in supplementing their farmers' income from milk by procuring dung and converting it into Bio CNG and fertilizer.

Key Points:

- The Deesa-Tharad highway in Gujarat’s Banaskantha district, catering to 90-100 vehicles daily, is India’s first and only gas-filling station based on dung from cattle and buffaloes.

- The ‘BioCNG’ outlet in Dama village of Deesa taluka, belonging to the Banaskantha District Co-operative Milk Producers’ Union, sells 550-600 kg of gas per day generated from 40 tonnes of dung at an adjoining four-acre plant.

Facts related to Dung

- An average adult bovine animal discharges 15-20 kg of fresh dung daily, while calves give out 5-10 kg.

- Fresh dung contains 80-85% water; one kg weighs hardly 200 grams on drying.

- A biogas plant requires fresh dung, which contains methane along with water.

- The methane is produced by bovines inside their rumen (first of four stomach compartments), where the plant material they eat gets fermented or broken down by microorganisms before further digestion.

- Carbohydrate fermentation leads to production of carbon-dioxide (CO2) and hydrogen.

- These are used by archaea (bacteria-like microbes in the rumen) to produce methane, which the animal expels either as gas or in the dung.

- The dung left to dry in the open releases both water and methane.

- To realize its fuel value, the dung has to, therefore, be collected and delivered in fresh form at the biogas plant.

- The union — India’s largest dairy concern, which procured an average 72.03 lakh kg per day (LKPD) of milk in 2022-23, including 5.74 LKPD from outside Gujarat — is paying farmers Rs 1/kg and bearing the cost of transporting the dung by five tractor-trolleys doing two trips a day.

|

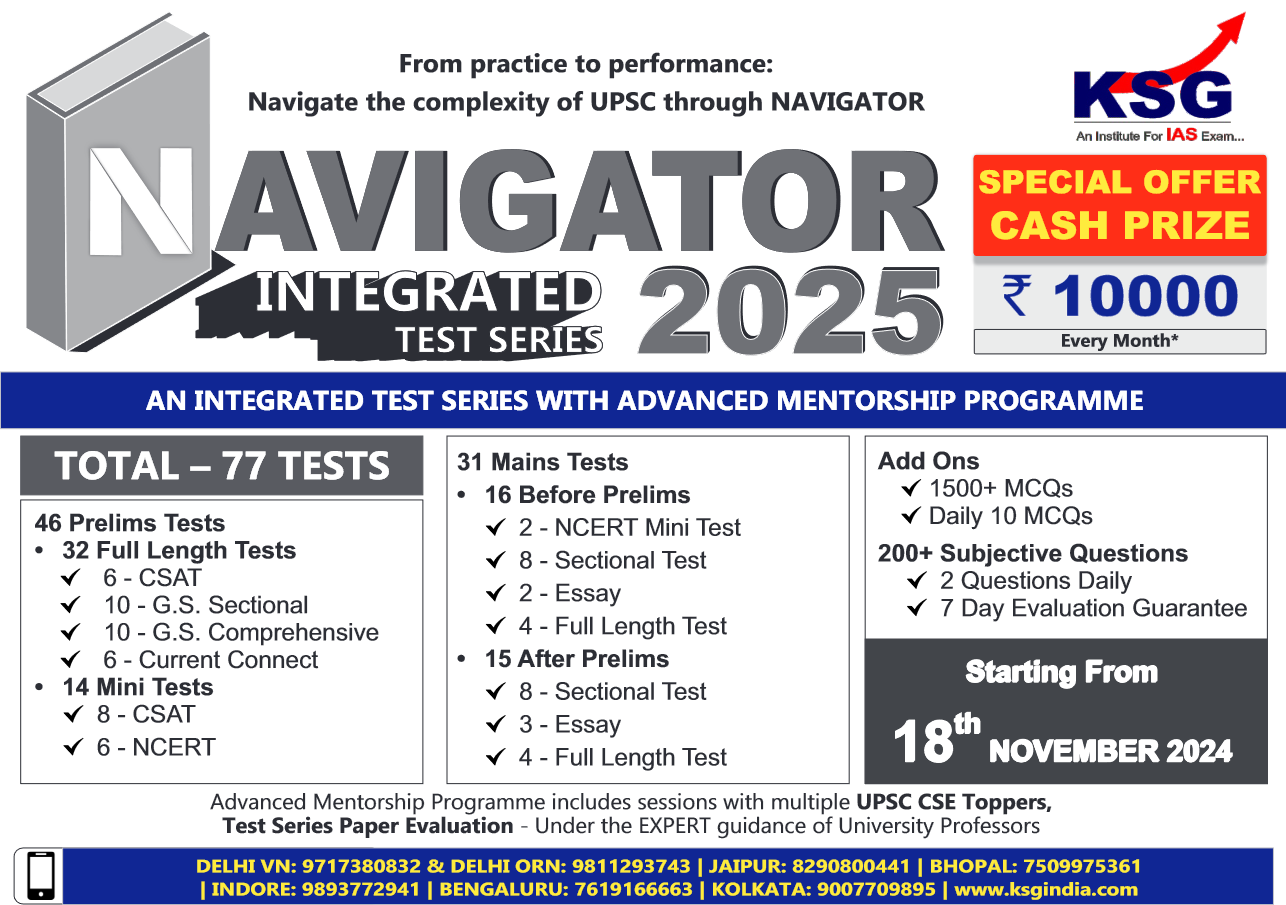

Process of making Biogas

|

Importance of Dung

- As a Fuel option:

- The compressed biogas (CBG), conveyed through pipelines to the dispensers at the fuel station, is what’s being sold as BioCNG at Rs 72/kg.

- As a Fertilizer option

- The slurry, from mixing 40,000 litres of water with 40,000 kg of dung, is a source of bio-fertiliser.

|

Process of making Biofertilizer

|

-

- The Banaskantha Union is currently marketing 8,000-10,000 kg of bio-fertiliser daily, with PROM (also called BioDAP, as a substitute for di-ammonium phosphate) fetching Rs 15-16/kg and compost Rs 8-10/kg.

- At an average realisation of Rs 12/kg, the Union’s revenues from bio-fertiliser sales are actually higher than from the 550-600 kg of BioCNG at Rs 72/kg.

- The 40 tonnes-per-day dung-based BioCNG plant, functional since August 2020, cost Rs 8 crore. The Banaskantha Union plans to commission four more, with 100 tonnes capacity each, by 2025.

- The Rs 230 crore investment in the four plants is to come from Suzuki Motor Corporation (India’s leading car maker), with the Banaskantha Union providing the land and the National Dairy Development Board handling project execution.

- Alternate options of using dung will help in increasing and doubling the income of farmers.

Issues with dung based fuel and fertilizer:

- However, widespread use of manure as fertilizer can cause a variety of issues, including pathogen transmission, eutrophication of soil and water bodies, and the release of massive amounts of greenhouse and toxic gases.

- Effect of Temperature on Biogas Production: Like other renewable energy sources (e.g. solar, wind), biogas generation is also affected by the weather. The optimal temperature bacteria needed to digest waste is around 37°C. In cold climates, digesters require heat energy to maintain a constant biogas supply.

- Less Suitable For Dense Metropolitan Areas: Another biogas disadvantage is that industrial biogas plants only make sense where raw materials (food waste, manure) are in plentiful supply . For this reason, biogas generation is much more suitable for rural and suburban areas.

Government Initiatives:

- Galvanizing Organic Bio-Agro Resources (GOBAR)-Dhan was launched by the Government of India in April 2018 as a part of the biodegradable waste management component under the Swachh Bharat Mission-Gramin.

- The scheme intends to positively impact village cleanliness and generate wealth and energy from cattle and organic waste.

- The main focus areas of GOBAR-Dhan are to keep villages clean, increase the income of rural households and generate energy and organic manure from cattle waste.

- ‘SATAT’ scheme on Compressed BioGas (CBG) encourages entrepreneurs to set up CBG plants, produce & supply CBG to Oil Marketing Companies (OMCs) for sale as automotive & industrial fuels.

- Biogas Programme: The objective of this programme is to support setting up of biogas plants for clean cooking fuel, lighting, meeting thermal and small power needs of users which ultimately results in GHG reduction, improved sanitation, women empowerment and creation of rural employment.

Conclusion:

Hence, It is the Banaskantha BioCNG plant or the Kaira Union’s less capital-intensive decentralized model, the good news is that the scope for additional income to dairy farmers from sale of dung is expanding.